For small businesses, getting your product on store shelves is a big accomplishment. Before you can celebrate, there’s a few important details that you need to get right: obtaining authentic GS1 brand-licensed GTINs and placing the UPC barcode on your product packaging. The UPC is more than just a barcode—it’s a crucial part of your product’s identity and plays a vital role in its ability to be sold in stores and online.

Incorrect placement of a UPC can lead to significant problems, especially for small businesses. Not only can it cause issues with scanning at checkout, but it can also result in chargebacks from retailers if the barcode doesn’t meet the placement guidelines established by the GS1 General Specifications. As the US authority on barcodes and implementation, we specialize in providing authentic UPC GTIN barcodes and ensuring they are correctly integrated on your packaging. In this article, we’ll walk you through the proper placement of UPCs on various types of product packaging and explain why getting it right is essential.

Understanding the Basics of UPC Placement

A GTIN is a unique code that identifies your product in the marketplace. The UPC barcode is the machine-readable symbol representing a GTIN used by retailers, distributors, and customers to scan and track your product throughout the supply chain. Proper placement of the UPC on your packaging is critical because it ensures that the barcode can be easily scanned and recognized at every stage, from the warehouse to the checkout counter. Checkout employees are trained on where to expect UPC barcodes on different product types, so they can efficiently and quickly scan customers’ products.

Whereas our company specializes in compliant barcodes and implementation, GS1 is solely the global standards organization that administers Company Prefixes/GTINs and establishes global standards. The GS1 General Specification is a comprehensive guide detailing GS1 identification models, applicable barcode languages, and implementation recommendations for various industries. The current document is over 500 pages and includes guidance for the placement of UPCs on product packaging to ensure consistency and reliability. However, many small businesses make the mistake of overlooking these guidelines, leading to problems that can affect their bottom line.

The Correct Placement of UPCs on Common Types of Packaging

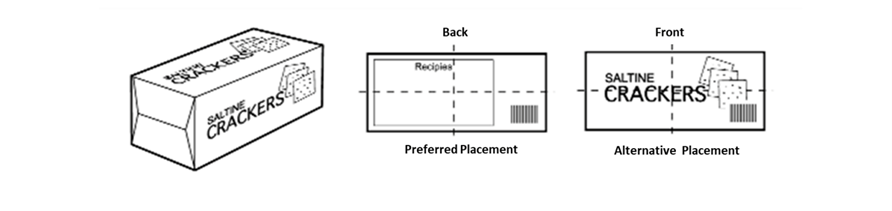

A. Flat Packaging (e.g., Boxes, Cartons)

For products packaged in boxes or cartons, the UPC should be placed on a flat, easily accessible surface. The ideal location is typically on the bottom or side of the package, where it won’t be obstructed by other design elements like logos or text. It’s important to leave enough white space around the UPC to ensure it can be scanned without interference.

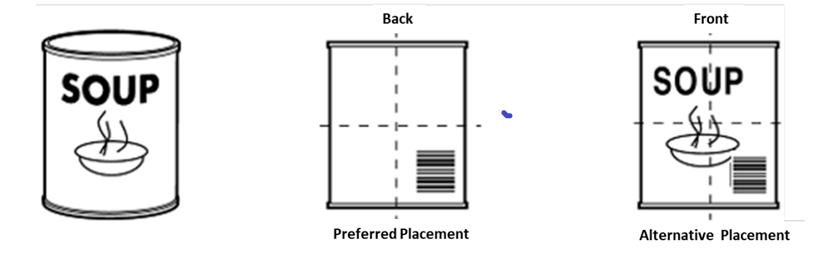

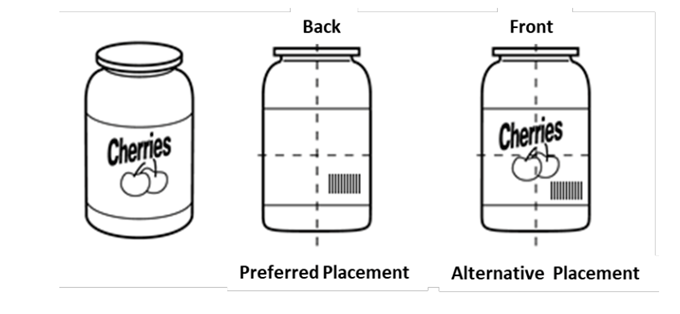

B. Cylindrical Packaging (e.g., Bottles, Cans)

Cylindrical packaging presents unique challenges for UPC placement. The barcode should be placed so that it wraps smoothly around the cylinder without distortion. Ideally, the UPC should be placed vertically along the height of the cylinder rather than horizontally around it. This orientation minimizes the risk of scanning errors caused by curving or warping of the barcode.

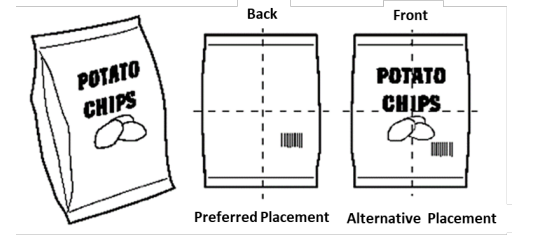

C. Flexible Packaging (e.g., Pouches, Bags)

Flexible packaging, such as pouches and bags, requires special attention when placing a UPC. The barcode should be placed on a flat, stable area of the packaging, where it won’t be distorted by folds, wrinkles, or crinkles. It’s crucial to test the packaging to ensure that the barcode remains scannable even when the package is handled or compressed.

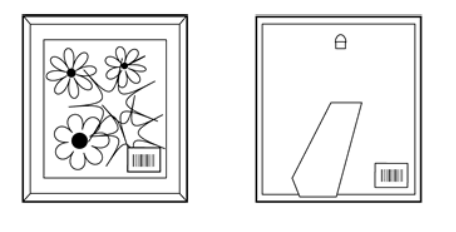

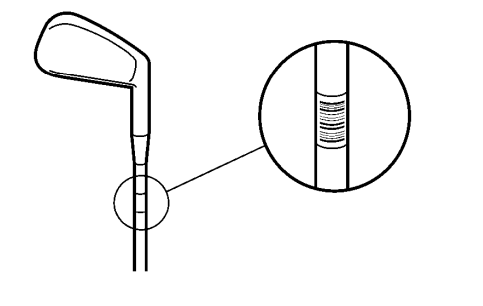

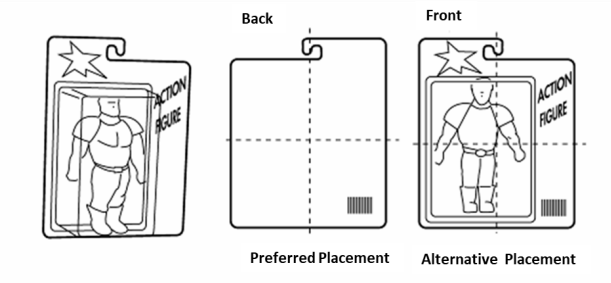

GS1 General Specifications: Source for Barcode Placement Information

The GS1 General Specifications are constantly being revised, and the current document is the 24th version. Whereas the original GS1 Placement Guideline provided an overview of placement recommendations, the new version of the General Specifications has detailed illustrations for different types of products and product packaging. The following illustrations are just a few of the products covered in the document. Our GS1 barcode consultants are well-versed in the specifications and are available to help clients navigate the requirements.

The current version of the GS1 General Specification now includes placement guidance for the upcoming 2027 GS1 Digital Link initiative. Since the UPC/EAN barcode is not going to be retired in the immediate future, the current guidance is to place the GS1 Digitial Link QR code within a set proximity to the UPC/EAN barcode symbol.

Consequences of Incorrect UPC Placement

For small businesses, the consequences of incorrect UPC placement can be severe. Retailers rely on accurate, scannable barcodes to manage their inventory and sales processes. If your UPC is not placed according to the guidelines, it may not scan correctly, leading to delays at checkout, frustrated customers, and even lost sales.

Moreover, many retailers have strict policies regarding barcode placement. If your UPC does not comply with these standards, you may face chargebacks—penalties imposed by retailers for non-compliant barcodes. For a small business operating on tight margins, these chargebacks can be financially damaging and harm your relationship with retailers.

In addition to financial consequences, improper UPC placement can also damage your brand’s reputation. Customers expect a seamless shopping experience and issues with scanning or product identification can lead to negative reviews and a loss of trust in your brand.

Best Practices for Ensuring Proper UPC Placement

To avoid the pitfalls of incorrect UPC placement, it’s important to follow best practices from the start. Here are some tips to help you get it right:

- Design with Barcode Placement in Mind: When designing your product packaging, consider where the UPC will be placed early in the process. Ensure that the area designated for the barcode is free from other design elements and has sufficient white space around it.

- Test for Scannability: Before finalizing your packaging, verify and test the UPC to make sure it can be easily scanned from various angles and in different lighting conditions. This step is especially important for flexible or cylindrical packaging, where the barcode’s readability can be affected by the shape and material of the package.

- Consult Experts: If you’re unsure about how to place your UPC correctly, seek advice from experts. At Barcode US, we provide guidance and support to ensure that your barcodes are compliant with global standards and are ready for the marketplace.

Proper placement of UPCs on product packaging is not just a detail—it’s a critical factor in your product’s success. For small businesses, following the placement guidelines set by GS1 and adopted by retailers is essential to avoid costly mistakes such as chargebacks, lost sales, and damage to your brand’s reputation.

By taking the time to understand and implement these guidelines, you can ensure that your product is ready for the market and that your UPCs work as intended. If you need assistance with barcode placement or have any questions about UPCs, our GS1 barcode consultants are here to help. As the US authority on authentic UPC GTIN barcodes, we’re committed to supporting small businesses in navigating the complexities of product identification and packaging.

Don’t let incorrect UPC placement stand in the way of your success. Contact us today to learn more about how we can help you place your barcodes correctly and avoid the pitfalls that can impact your business.

Comments are closed.