Barcode Verification is more than Print Quality

Paul took his UPC barcode to the local grocery store and asked the cashier to scan it. He was told, “Sorry. It doesn’t work”. It scanned previously with a grade of A, so he couldn’t figure out the problem. This type of miscommunication is common between vendors and stores. No explanation is provided, so the assumption is that the barcode just doesn’t scan, when actually the underlying issue is not a print quality related problem. In Paul’s case the barcode image scanned, it just wasn’t recognized by the system, which is related to a data issue. Making sure the barcode scans with a passing grade is essential but what we have to remember is that other areas must also be verified. The barcode symbol must also pass additional checks to ensure it is capable of serving the intended purpose. Factors such as symbology/barcode language, data, and dimensions play a huge roll when verifying a barcode symbol. In addition to print quality, these factors should also be verified through barcode verification.

Paul took his UPC barcode to the local grocery store and asked the cashier to scan it. He was told, “Sorry. It doesn’t work”. It scanned previously with a grade of A, so he couldn’t figure out the problem. This type of miscommunication is common between vendors and stores. No explanation is provided, so the assumption is that the barcode just doesn’t scan, when actually the underlying issue is not a print quality related problem. In Paul’s case the barcode image scanned, it just wasn’t recognized by the system, which is related to a data issue. Making sure the barcode scans with a passing grade is essential but what we have to remember is that other areas must also be verified. The barcode symbol must also pass additional checks to ensure it is capable of serving the intended purpose. Factors such as symbology/barcode language, data, and dimensions play a huge roll when verifying a barcode symbol. In addition to print quality, these factors should also be verified through barcode verification.

What is Barcode Verification?

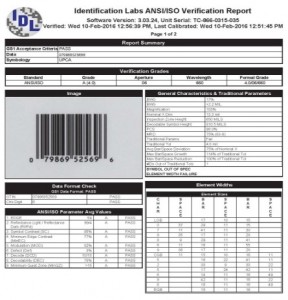

Barcode verification is basically a safety check performed on a barcode symbol to determine how well it will scan by the end user. The barcode is tested using a barcode verifier and the results are usually assessed against a standard or specified requirement. One example of a standards document would be the GS1 General Specifications, which is the standard that businesses follow to communicate with one another when using barcodes. Another example would be the ANSI/ISO standard, which is used to measure print quality developed by the American National Standards Institute and the International Standards Organization. In regards to specific store requirements, generally they publish a document which lays out their barcode guidelines. In order to interpret the verification results correctly you’ll need to know which standard or requirement applies to use as a reference point.

Barcode verification is basically a safety check performed on a barcode symbol to determine how well it will scan by the end user. The barcode is tested using a barcode verifier and the results are usually assessed against a standard or specified requirement. One example of a standards document would be the GS1 General Specifications, which is the standard that businesses follow to communicate with one another when using barcodes. Another example would be the ANSI/ISO standard, which is used to measure print quality developed by the American National Standards Institute and the International Standards Organization. In regards to specific store requirements, generally they publish a document which lays out their barcode guidelines. In order to interpret the verification results correctly you’ll need to know which standard or requirement applies to use as a reference point.

One may see barcode verification as the link between creating a barcode symbol and confirming the symbol will work once it reaches the intended destination. One of the most important aspects of barcode verification is the print quality analysis, which measures how well a barcode symbol will scan once it reaches the end user. However, verifying data content, barcode symbology, and barcode dimensions is of equal importance. Barcode print quality is imperative, but can be meaningless, if the data is flawed or the incorrect barcode symbology is used.

The barcode scans fine. I don’t understand the problem.

Barcodes created with the incorrect barcode language may receive a passing ANSI/ISO print quality grade but at the same time could be useless. Each barcode language has a specified use. Databars are used for coupons, QR Codes (Quick Response Codes) are used for marketing campaigns, EAN-13s (International Article Number) are used to identify books, UPCs (Universal Product Code) are used for retail point of sale, ITF-14 and SSCC-18 (Serialized Shipping Container Code) barcodes are used to identify logistics units, and the list goes on and on. Since each language has a predefined purpose and requires predefined data, the scanning equipment used may or may not be equipped to read the barcode symbol if the incorrect language is used. For instance, if a t-shirt is labeled with an ITF-14 barcode, to be scanned at point of sale, it would be non-scannable. This is because scanners used at point of sale are programmed to scan point of sale barcodes, not logistic barcodes. It’s imperative to verify the barcode language during the barcode verification process to make sure the language being used applies to the data being encoded and how the barcode will be used.

Barcodes created with the incorrect barcode language may receive a passing ANSI/ISO print quality grade but at the same time could be useless. Each barcode language has a specified use. Databars are used for coupons, QR Codes (Quick Response Codes) are used for marketing campaigns, EAN-13s (International Article Number) are used to identify books, UPCs (Universal Product Code) are used for retail point of sale, ITF-14 and SSCC-18 (Serialized Shipping Container Code) barcodes are used to identify logistics units, and the list goes on and on. Since each language has a predefined purpose and requires predefined data, the scanning equipment used may or may not be equipped to read the barcode symbol if the incorrect language is used. For instance, if a t-shirt is labeled with an ITF-14 barcode, to be scanned at point of sale, it would be non-scannable. This is because scanners used at point of sale are programmed to scan point of sale barcodes, not logistic barcodes. It’s imperative to verify the barcode language during the barcode verification process to make sure the language being used applies to the data being encoded and how the barcode will be used.

We always use this number. How can my data be wrong?

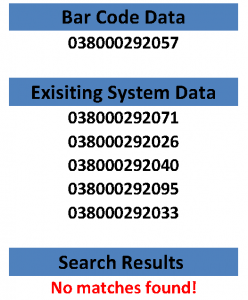

Encoding the correct data in a barcode symbol is critical. Generally barcodes are used to quickly find or enter information into a system. If you are searching for information and scan a barcode with bad data, you’ll never find what you’re looking for. On the flip side, if you’re entering information from a barcode that has bad data, your system will be polluted with inaccurate information. Both situations have the potential to result in havoc and annoying headaches, just like Paul is experiencing.

Encoding the correct data in a barcode symbol is critical. Generally barcodes are used to quickly find or enter information into a system. If you are searching for information and scan a barcode with bad data, you’ll never find what you’re looking for. On the flip side, if you’re entering information from a barcode that has bad data, your system will be polluted with inaccurate information. Both situations have the potential to result in havoc and annoying headaches, just like Paul is experiencing.

Now let’s revisit Paul’s problem. He can’t figure out why his UPC wasn’t recognized at the local grocery store. There are several possible reasons why this could happen, but based on our customer inquiries, we’ve learned the most common reason is the UPC number is not scanning because it was never entered into the store’s system (vendors should consult the store on the proper procedure for providing item information). It is also possible that the incorrect number of digits was provided. For example, if Paul gives the store a 13-digit number and encoded 12 digits in the barcode, the data would be misaligned. Products labeled with unrecognized UPCs result in a delay in sales and unhappy customers.

Data issues may also come up when incorrect attributes are used. Data Identifiers and Application IDs (AIs) are used to identify the type, length, and format of the data encoded in a barcode symbol. The difference between the two is AIs are only used with GS1-128 barcodes. For example, if you’re creating a SSCC-18 barcode, the AI is always (00) and alerts the scanning equipment that an 18 digit SSCC-18 number will follow. The same concept applies with Data Identifiers. If 4L is used, the scanning equipment expects a two letter country code will follow (representing the Country of Origin). The key point to remember is if data attributes are not entered properly the data cannot be decoded properly.

It’s really close. Is this a big issue?

In a nutshell, barcodes printed too big or too small stand a chance of not scanning. This is why meeting the minimum but not exceeding the maximum size requirement is so important. The environment in which a barcode will be scanned determines what type of barcode scanning equipment should be used, thus the minimum and maximum sizes allowed. For example, let’s take a look at the SSCC-18 barcode. This type of barcode appears on GS1-128 shipping labels and is used to identify logistic units. These labels are placed on shipping cartons which are scanned in distribution centers to sort and receive merchandise through an automated process. The cartons are placed on conveyor belts and scanned with high speed sortation devices. Per the GS1 General Specifications v16, SSCC-18 barcodes scanned in general distribution must have a minimum X dimension of 0.0195 inches and cannot exceed 0.0400 inches. Since most scanning equipment is built to accommodate the GS1 standards symbols, barcodes that do not meet the minimum may not get recognized by the scanning equipment. Remember the cartons are moving quickly on conveyer belts and must read on the first try, there is little room for error. Of course there are tolerances in place to address extreme cases but shouldn’t be used a crutch. Be sure to allow enough space for the symbol being printed to avoid any size restrictions.

In a nutshell, barcodes printed too big or too small stand a chance of not scanning. This is why meeting the minimum but not exceeding the maximum size requirement is so important. The environment in which a barcode will be scanned determines what type of barcode scanning equipment should be used, thus the minimum and maximum sizes allowed. For example, let’s take a look at the SSCC-18 barcode. This type of barcode appears on GS1-128 shipping labels and is used to identify logistic units. These labels are placed on shipping cartons which are scanned in distribution centers to sort and receive merchandise through an automated process. The cartons are placed on conveyor belts and scanned with high speed sortation devices. Per the GS1 General Specifications v16, SSCC-18 barcodes scanned in general distribution must have a minimum X dimension of 0.0195 inches and cannot exceed 0.0400 inches. Since most scanning equipment is built to accommodate the GS1 standards symbols, barcodes that do not meet the minimum may not get recognized by the scanning equipment. Remember the cartons are moving quickly on conveyer belts and must read on the first try, there is little room for error. Of course there are tolerances in place to address extreme cases but shouldn’t be used a crutch. Be sure to allow enough space for the symbol being printed to avoid any size restrictions.

Barcode Verification Tips

If you are doing a quick internal check or a thorough barcode verification analysis, there two things one should remember. The first is you have to know what you need. If you are unsure of what standard to follow you’ll have no way to determine if the results are correct or incorrect. Secondly, the right type of verification equipment must be used properly. Using the right aperture and regularly calibrated equipment will lead to accurate results. Without a clear understanding of what is needed, in addition to the improper use of verification equipment, you’ll only get inaccurate results.

If you are doing a quick internal check or a thorough barcode verification analysis, there two things one should remember. The first is you have to know what you need. If you are unsure of what standard to follow you’ll have no way to determine if the results are correct or incorrect. Secondly, the right type of verification equipment must be used properly. Using the right aperture and regularly calibrated equipment will lead to accurate results. Without a clear understanding of what is needed, in addition to the improper use of verification equipment, you’ll only get inaccurate results.

This article was written by Tammi Slaughter. Tammi is a member of the Identification Labs compliance team and is a GS1 Certified Barcode Professional.

Comments are closed.