“How Could This Possibly Be My Responsibility?” said Supplier Who Received The Offset

Receiving barcode compliance offset charges quite often makes suppliers cringe. We should know because our testing division, Identification Labs, administers and validates barcode compliance charges for many retailers and distributors. The companies which utilize our services trust our lab to provide unbiased testing and verification to support barcode compliance charges. Both abrasion and smudging issues are commonly misunderstood by suppliers and can be normally avoided.

The Responsibilities of Being a Label Printer

Before desktop publishing and on-demand printers, printed labels were only manufactured by companies that specialized in printing various types of labels. Those companies were called “printers”. These companies used printing processes that involved a substantial amount of quality control protocols. Every aspect of the printing process was statistically measured and recorded. All label material would be specified and evaluated for moisture content and compliance before labels were printed.

Today, almost every manufacturing company performs some form of label printing but most do not integrate any form of quality control for material and print quality. It is very common for the printing processes to be performed by the lowest hourly paid employee at an organization and the purchasing of materials is handled by a completely different department. To properly address abrasion and smudging issues, companies need to proactively work with their label material suppliers. There are solutions that work for most supply chains.

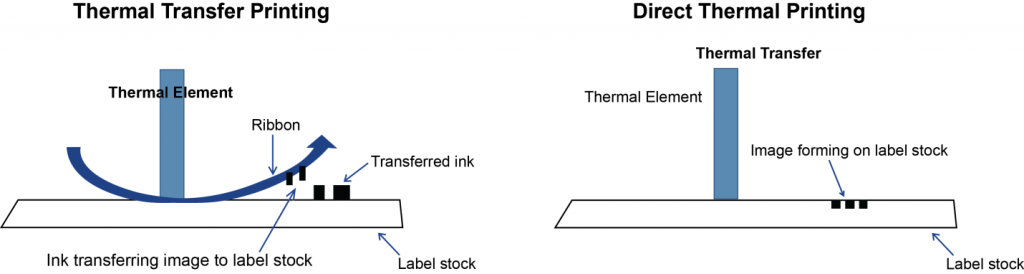

Thermal Transfer vs. Direct Thermal

Aside from laser printers, thermal printers are typically used for on-demand printing. Both thermal transfer and direct thermal printing use a thermal element, called a printhead, to image dark bars. Thermal transfer printing utilizes a ribbon to create a printed image on label stock. The printer applies heat to the ribbon, which transfers the wax and/or resin onto the label.

With direct thermal printing, heat is applied directly from the printhead to the label stock, causing the stock to blacken resulting in the image. Although direct thermal is quite cost-effective, the labels may not always be able to withstand the shipping process compared to thermal transfer printed labels. Direct thermal labels are heat-sensitive, and the printed image can degrade in hot environments. There have been tremendous improvements to the face stock which has made direct thermal printing more popular in recent years.

The factors which impact barcode print quality involve either printer settings or print media. Both the speed at which labels pass through a printer and the amount of energy (heat) set on the printhead will affect the widths of individual bars within a barcode. When the speed of the printer is reduced, the printhead has more time to image a dark bar element. Just as when the heat setting on a printhead is set higher, the thickness of a bar element is also increased. Although printer settings for a thermal transfer imaged label may result in excess ribbon being “transferred”, smudging and abrasion problems commonly result from an issue with print media.

Thermal Transfer Printing: Smudging

Smudging occurs on-demand printing when the transferred ribbon does not permanently adhere to the face stock of the label. There are different types of thermal transfer ribbons which can range from an all wax to a resin-based ribbon. The resin-based ribbon can fuse better with most label stocks and provide a permanent image. Conversely, all wax ribbons provide the least durable image and are normally less expensive. The imaging from an all wax ribbon can typically be smeared by light rubbing a finger or pencil. All print media providers have a range of ribbon materials composed of both resin and wax.

Thermal Transfer Printing: Smudging and White Defect Marks

As referenced above, a thermal transfer ribbon is often the culprit for issues of smudging. However, it is extremely important to note that there needs to be a good marriage between the face stock of the label and the ribbon used. The face stock of a label can be coated with a material that does not enable the transferred ribbon to correctly bond. Consequently, smudging and white flakes occur when the face stock is not correctly matched. A good label material provider will only provide label/ribbon combinations to avoid these types of issues.

Thermal Transfer & Direct Thermal Printing: Abrasion

Cartons traveling in every iteration of supply chain logistics will endure some form of abrasion. There are numerous factors that impact the amount of pressure a carton and/or label will experience during transportation. Cartons packed in larger cargo containers and traveling longer distances will typically experience more logistics-related friction than cartons loaded into a single trailer going to a nearby distribution center. In addition, elevated storage temperature will have an adverse effect on certain types of label material. For scanning environments where cartons are read while moving at a high velocity, the impact from abrasion issues is magnified.

In the scope of barcode label compliance, abrasion is a result of an inadequate face stock that results in marring or discoloration with light friction. Although this issue is more common with direct thermal stock, it has recently been occurring more with thermal transfer label material as well. Label materials used for logistics must be resistant to a reasonable level of abrasion.

Unlike barcode print quality, there are no ISO standards that have been adopted by GS1 or retail associations for abrasion resistance. For compliance issues involving abrasion, our testing analysts use mechanical scratch and friction tools to access the severity of abrasion. If the actual label face stock is physically damaged when viewing under an electronic microscope, we will normally invalidate an abrasion claim and the suppliers are not charged for the infraction. Conversely, if marring occurs with easy friction pressure, we normally validate the compliance charge since the label face stock should not easily be marked. When working with suppliers, our testing analysts recommend that a company can perform a simple pre-diagnostic manual testing with a pen cap or fingernail in the upper portion of a label. If the label easily shows a dark mark with light manual friction, it will probably not perform well in any logistics supply chain.

Proactive Prevention

“An Ounce of Prevention Is Worth a Pound of Cure” – Benjamin Franklin

The harsh truth is that labels that cost less than $0.05 apiece can result in thousands of dollars of barcode compliance offset charges. The significance of barcode print quality is dependent on both individual logistic supply chains and the scanning environments. Not every major retailer or distributor uses high-speed sortation scanners to capture barcode data and that is why companies may be receiving a disproportionate amount of infractions from one particular trading partner.

Some suppliers view barcode compliance charges as a “profit center” for retailers but as an unbiased testing center, we can attest that the infractions we are processing are very much valid. The retailers that utilize our compliance administration services, empower us to support the compliance offsets and protect their suppliers’ interests against inaccurate barcode reporting.

To resolve infractions involving abrasion and smudging, companies need to work directly with their print media provider to identify the best and most economical solution for particular supply chains. Once a few options are provided, we recommend that companies submit samples to our testing lab for evaluation. To submit a test, please visit www.barcode.graphics/identification-labs-testing/ .

Bar Code Graphics is a leader in barcode print quality and is the largest North American barcode testing center for POS and shipping labels. Please feel free to call us at 800.662.0701 x310 or email us at support@barcode-us.com.

Related : Top 5 Frequent Thermal Printing Barcode Problems & How They Can Be Prevented

Comments are closed.