Printing barcodes from PDF files can present significant challenges that often go unnoticed until it’s too late. Unlike text and images, poor barcode print quality isn’t always apparent to the naked eye, leading to non-scannable barcodes that can cause substantial financial penalties. Companies like Amazon impose a $0.25 charge for each item requiring manual relabeling, while large retailers may charge $5 to $10 per carton needing manual rework. This issue highlights the importance of understanding and addressing barcode printing nuances to avoid costly errors and ensure compliance.

With the rise of desktop publishing and in-house printing, many businesses underestimate the potential liabilities associated with barcode printing. Solution providers often supply PDF images of barcode shipping labels for clients to print on their equipment.

However, this practice isn’t foolproof, as various factors—such as the software used to generate the PDFs, user settings, and printer specifications—can all impact the quality of the printed barcodes. Just as companies need to understand the limitations of low-resolution files, such as JPG and PNG, for printing UPC barcodes on packages, proper guidance and additional instructions are essential to ensuring clients using PDF files to print their shipping labels achieve compliant, scannable results.

Using PDF images to produce barcode shipping labels can be effective when implemented correctly. Our testing division, Identification Labs, evaluates thousands of barcoded shipping labels annually and frequently assists retailer suppliers struggling to certify. Unfortunately, many solution providers fail to offer adequate instructions, resulting in non-compliant shipping labels. This article addresses the crucial factors that both solution providers and users must consider to ensure the correct printing of compliant barcode labels.

What Are PDF Files?

A PDF (Portable Document Format) file is a type of document that looks the same on any device or software and is vector-based, meaning it optimizes for the resolution of the selected output device. It keeps all the text, images, and formatting intact, making it ideal for sharing and printing. While PDFs ensure consistent appearance, the accuracy of objects like barcodes may not always be precise, potentially leading to issues in specific applications.

What is Complicated About Printing Barcodes?

Linear barcode symbols rely on precise spacing and line thickness to be scannable, which can be easily distorted during printing. Unlike visible objects like pictures and text, barcodes are vector-based and need to be optimized for the specific resolution of the printer. Even slight variations in printing settings, such as scaling, resolution, or print quality, can render a barcode unreadable, leading to significant issues in applications that require barcode accuracy. Scanning environments involving automation magnify the importance of printing precision.

The ISO 15416 standard provides a grading methodology to determine the precision of linear barcode symbols. This grading evaluates barcodes based on several criteria, such as decodability, edge contrast, modulation, and defects, to ensure they can be accurately scanned. Each barcode receives a grade from A to F, indicating its overall quality and readability. The GS1 Global Standards and retailers rely on ISO barcode print quality grades to ascertain suppliers’ abilities to provide barcodes that will work within their supply chains.

When barcodes are included in PDF files, their decodability grade can be impacted due to resolution changes or scaling during printing. These alterations can distort the precise spacing and line thickness required for barcodes, making them difficult or impossible to scan correctly. Thus, its accuracy might be compromised even if the barcode appears crisp visually.

Impacting Factors

Issues with barcode quality when printing from PDF files can stem from various factors. These problems may arise due to how the original PDF was generated by a solution provider or software,. Additionally, user settings and equipment can play a significant role. Factors such as printer resolution, paper quality, and print settings, as well as the calibration and maintenance of the printing equipment, can all impact the final barcode quality, leading to decodability issues.

User & Equipment Issues

– Printer Resolution

When a barcode is generated as a PDF and then printed, the resolution of the image might not be sufficient, causing the edges of the bars to blur or become jagged, impacting the barcode’s decodability. To ensure optimal scan quality, it is crucial to print the PDF at a high resolution, preferably 300 DPI or higher. Some thermal transfer printers with 203 DPI will work for particular-size barcodes. This practice helps maintain sharp, clean edges on the barcode, enhancing its readability and compliance with ISO/ANSI standards.

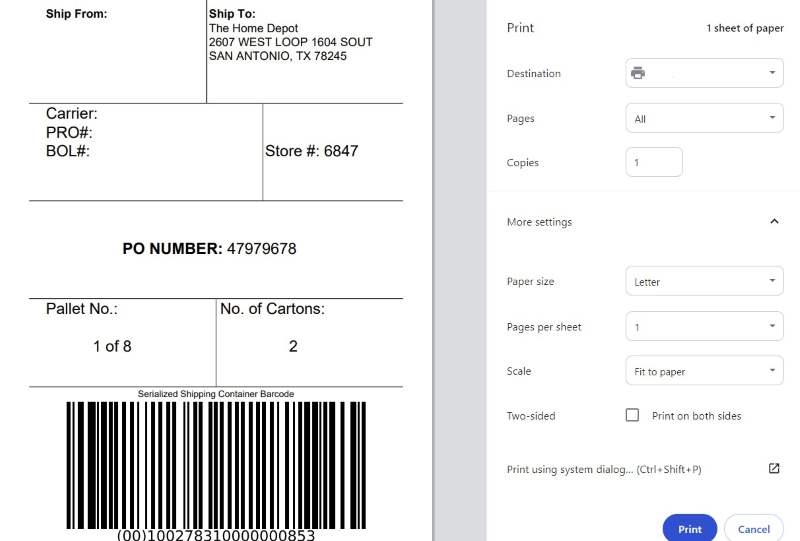

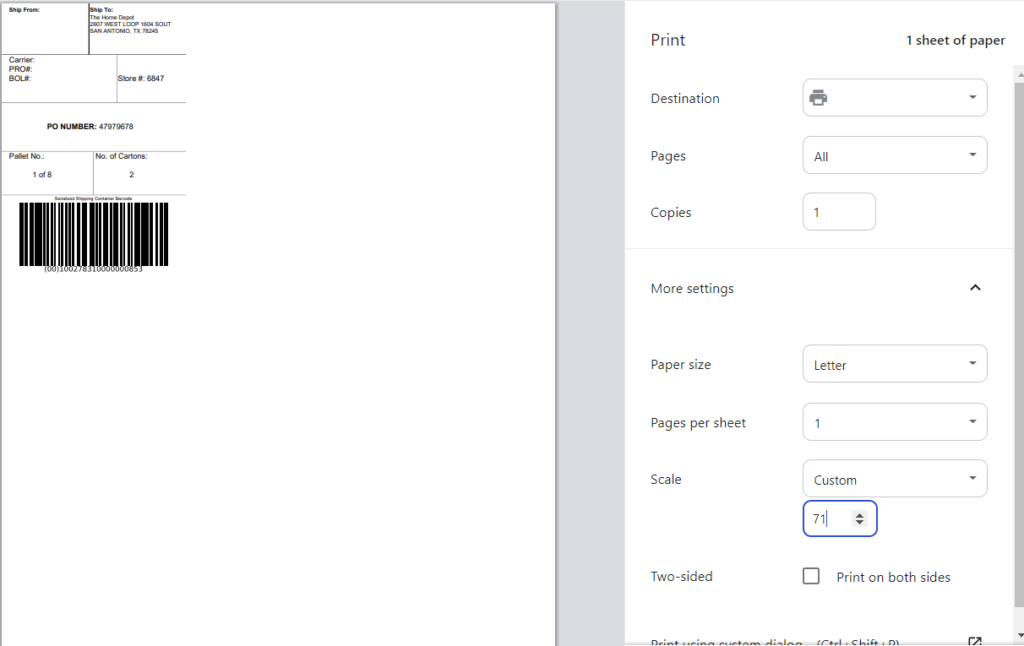

– Scaling

When printing from a PDF, the document might be scaled improperly, either intentionally or unintentionally. This can distort the barcode, changing the width of bars and spaces, which are critical for accurate decoding. The examples below show a decrease from 100% and also a scale instruction to fit to paper. Both are examples of what should NOT be done.

– Printer Settings

Every printer type has a software component, called a print driver. Each print driver may have various settings that can alter a barcode’s ability to scan correctly.

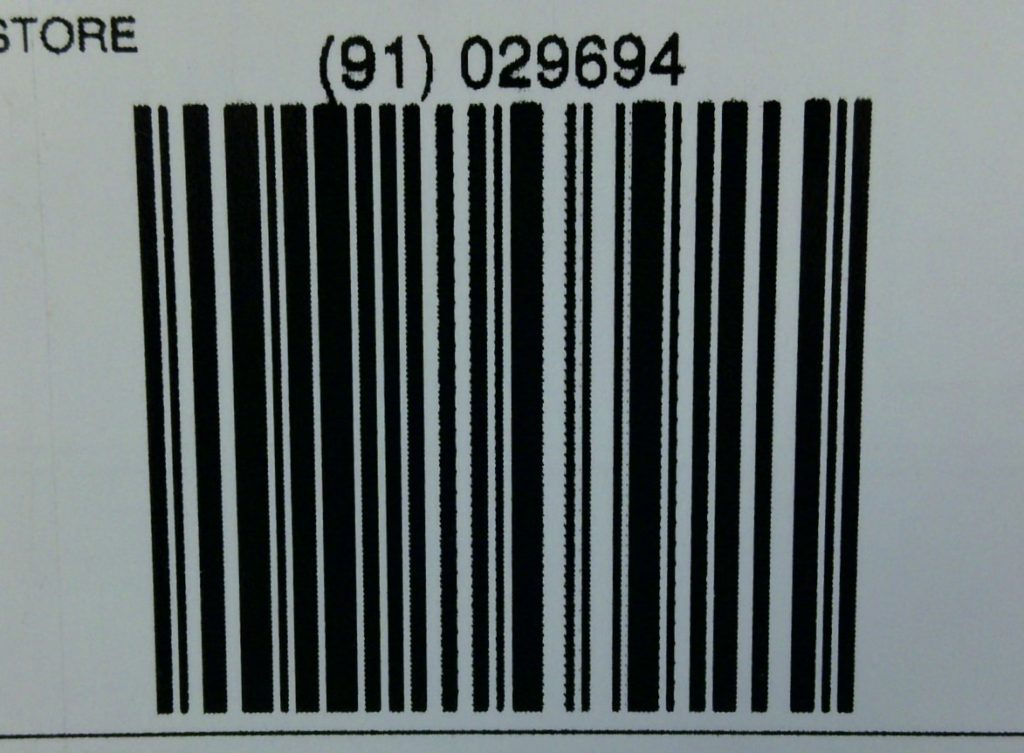

- Dithering: A setting that varies the density and pattern of tiny dots. Dithering can unintentionally occur if the printer’s resolution settings or the PDF’s conversion processes are not properly managed. This can cause the barcode’s solid lines to appear as a series of dots or uneven edges.

- Smoothing: An option to make the edges of images and text appear less jagged by averaging the colors of the pixels along the edges. When printing barcodes from a PDF, smoothing can alter the precise edges of the barcode lines, making them appear blurred or less defined. This can distort the exact spacing and thickness of the bars, which are crucial for accurate scanning and readability.

- Resolution Enhancement: An option that improves the sharpness and detail of images and text. When printing a barcode from a PDF, resolution enhancement can modify the original barcode’s precise line thickness and spacing by adding extra pixels to smooth out the edges. While this can make regular images and text look better, it can distort the barcode’s exact dimensions.

- Margins/Alignment: Misalignment or incorrect margins can distort the barcode during printing.

– Print Quality Issues

On-demand printers have settings that enable users to adjust the thickness of the toner or ribbon applied to a label. Poor print quality can cause toner/ribbon to spread beyond the intended lines of the barcode, which can make the bars wider than they should be and spaces narrower, leading to decoding errors.

– Software Rendering Issues

Software rendering issues occur when converting or displaying a PDF file, particularly with complex elements like barcodes. These issues can arise from differences in how various PDF viewers and printers interpret the document. When a barcode is rendered by software, subtle changes in line thickness, spacing, or resolution can occur, leading to distortions. These changes might not be noticeable visually but can make the barcode unscannable. There are different types of software to open and print PDF files, so it is recommended to discuss options with the solution provider.

PDF Generation Issues By Solution Provider

It is very common for EDI and other technology solution companies to provide barcode shipping labels in PDF formats, due to their general universal acceptance. However, there are numerous aspects of the generation component that are often misunderstood or overlooked. Many of the companies we have spoken to over the years are ill-informed with the nuances impacting barcode print quality. Consequently, many of their clients get caught in a “Catch-22” situation. Understanding the following PDF generation issues may help them rectify their solution problems.

- Embedded Fonts and Graphics: A crucial factor for ensuring that the label appears as intended on any device. For barcodes, the fonts and graphics need to be embedded correctly to maintain their precision. If the barcode font isn’t embedded, it may be substituted with a default font, distorting the barcode’s appearance. Additionally, embedded graphics must be rendered accurately to preserve the barcode’s line thickness and spacing. Any alterations during printing, like scaling or resolution changes, can affect the barcode’s scannability and compliance.

- Compression Artifacts: PDF files often use compression to reduce file size. If the compression algorithm is lossy, it means that some image data is permanently discarded to reduce the size of the file. This degradation can affect the sharpness and clarity of barcode images, causing the edges of the bars to blur or become distorted. Consequently, this loss in image quality can lead to poor decodability of the barcode, making it difficult for scanners to read accurately. To prevent this, it’s recommended to use lossless compression methods for PDFs containing barcodes.

Any software solution company that provides PDF labels should have ISO/ANSI barcode verification equipment to address the above factors during their programming. There are many available barcode libraries and fonts that can be integrated within a solution, and it is up to the software company to determine which will provide client-printed barcode labels that consistently will be acceptable in all scanning environments.

Conclusion

Printing barcode shipping labels from PDFs presents several challenges that can lead to significant issues if not properly addressed. These problems highlight the necessity for careful attention to detail and proper instructions from solution providers to ensure compliance and avoid costly errors.

By understanding the complexities involved in printing barcodes from PDFs, companies can take proactive steps to mitigate potential problems. Ensuring high-quality printing standards and following best practices can help maintain the accuracy and scannability of barcodes, ultimately preventing financial penalties and operational disruptions. It’s crucial for businesses to recognize the importance of these details to ensure smooth and efficient operations in their supply chain processes.

Comments are closed.