Since 1997 we have been administering barcode compliance programs for major retailers and there is always a significant increase in logistical barcode infractions during the fall. Due to apparent training challenges, the recent volume of non-compliant barcodes and subsequent offset expenses has been astronomical.

Many suppliers view barcode compliance charges as a “profit center” for retailers but as an unbiased testing center, we can attest that the infractions we are processing are very much valid. The retailers that utilize our compliance administration services, empower us to support the compliance offsets and protect their suppliers’ interests against inaccurate barcode reporting. Their supply chains are dependent on automated receiving processes, which require suppliers to be in 100% compliance with their carton label requirements.

The most effective way to reduce and/or eliminate offset expenses is to focus on improving performance. Recommended steps include:

- Routinely review your trading partners’ requirements. Convey this information to key personnel at your company. For example, JCPenney suppliers are encouraged to visit their web portal weekly.

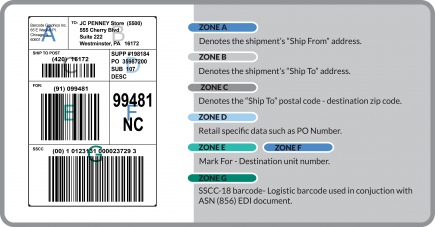

- Do not assume your company is in compliance. Confirm your company’s compliance by certifying your GS1-128 shipping labels. New personnel and system changes require updated certification for each retailer whose business you value. A $75 testing/certification fee can prevent unnecessary compliance offsets. We consistently see an increase in label defects from previously certified suppliers who made changes to their label material.

- Emphasis the importance of GS1-128 Shipping Label Placement to all personnel responsible for handling cartons. Placement requirements vary among retailers so education is key. Over 25% of all label offsets in the last quarter involved incorrectly placed GS1-128 labels.

Perform routine maintenance on printing equipment and confirm supplies are suitable for your application. If you are having issues with print quality, changing your print heads may solve the problem. We also recommend you always have spare print heads in-house at all times. Print quality infractions account for the largest percentage of GS1-128 issues and can be eliminated by proactive quality control that ensures consistent label compliance.

Perform routine maintenance on printing equipment and confirm supplies are suitable for your application. If you are having issues with print quality, changing your print heads may solve the problem. We also recommend you always have spare print heads in-house at all times. Print quality infractions account for the largest percentage of GS1-128 issues and can be eliminated by proactive quality control that ensures consistent label compliance.

For the retailers that we partner with, we’re able to promote and guide suppliers to certification immediately after any shipping label related compliance issues. In some cases, re-certification is simply built into the compliance process – if a label fails in the supply chain that means you automatically need to certify a corrected sample.

For the retailers who we aren’t integrated for compliance, we still test those labels but it depends on a supplier taking the initiative. Every day we test labels from retailers like Dick’s, Target, and Macy’s. These are from suppliers that are taking control of their compliance and focused on reducing offsets.

Last but not least, if you’ve received an offset for your shipping labels that was a little sparse on details or just didn’t seem right, certification will help build your case that an offset was taken in error.

Retailer suppliers are highly encouraged to read our 2019 GS1-128 Shipping Label Implementation Report.

Bar Code Graphics is a leader in barcode print quality and is the largest North American barcode testing center for POS and shipping labels. Please feel free to call us at 800.662.0701 x310 or email us at support@barcode-us.com. Information on our in-house barcode testing group can be viewed at www.identificationlabs.com.

Comments are closed.